|

|

|

| |

|

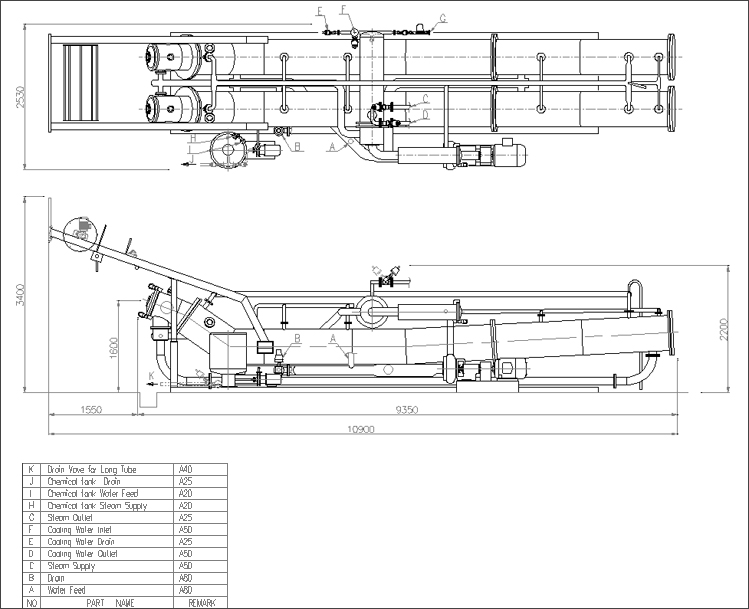

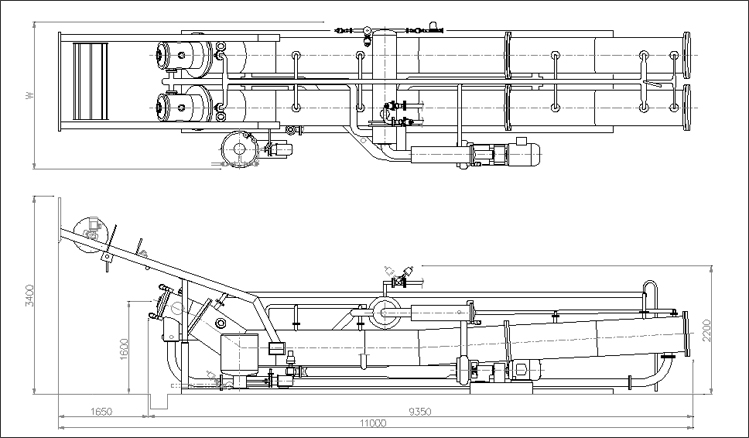

JET FLOW DYEING MACHINE SIDC 80b |

|

|

|

|

Features

• Through combination of stabilized jet nozzles and free-reelsЈо using cam clutches, low tension and high speed operation is possible. Which then results lesser spots, slanted wrinkles and twists. It also aids the material to relax.

• Water, steam and chemicals used are reduced by low liquid operations.

• Liquid Ratio ; 1:5~6

• Lower working door enables easier operations.

• Narrower installation width enables easier installations.

• Numerous processes including new synthetic thin fabric, spandex, knit dyeing, weight reduction and anti-flaming processing are possible. Relaxer processing for high density fibers including PET, sea -island fibers, micro fibers and NP composite fibers |

|

|

| |

|

|

| Model |

DC 81b |

DC 82b |

DC 83b |

| Loading Capacity (kg) |

70~200 |

140~400 |

210~600 |

| Liquid Quantity (liters) |

1,000~1,200 |

2,000~2,400 |

3,000~3,600 |

| Electric Power (kW) |

18.6 |

36.2 |

53.4 |

| Installed width (mm) |

1,650 |

2,550 |

3,550 |

| Length (mm) |

11,000 |

11,000 |

11,000 |

| Height (mm) |

1,600(3,600) |

1,600(3,600) |

1,600(3,600) |

| Max. operating temperature |

140ЁЩ |

|

|

| Heating rate (Saturate Steam 0.7Їч) |

Approx. 20min (from20ЁЩ to140ЁЩ) |

|

| Cooling rate (Cooling Water 0.1Їч, 15ЁЩ) |

Approx. 15min (fom140ЁЩ to 80ЁЩ) |

|

|

|

| |

|

|

|